Before interconnecting the cells, I spent some time yesterday making sure everything was ready. I added orange flex-guard around all of the exposed HV cables, and modified my power junction box to be more easily accessible (but still covered to keep curious fingers away):

I also mounted the 10A fuse for the DC-DC converter in an electronics box:

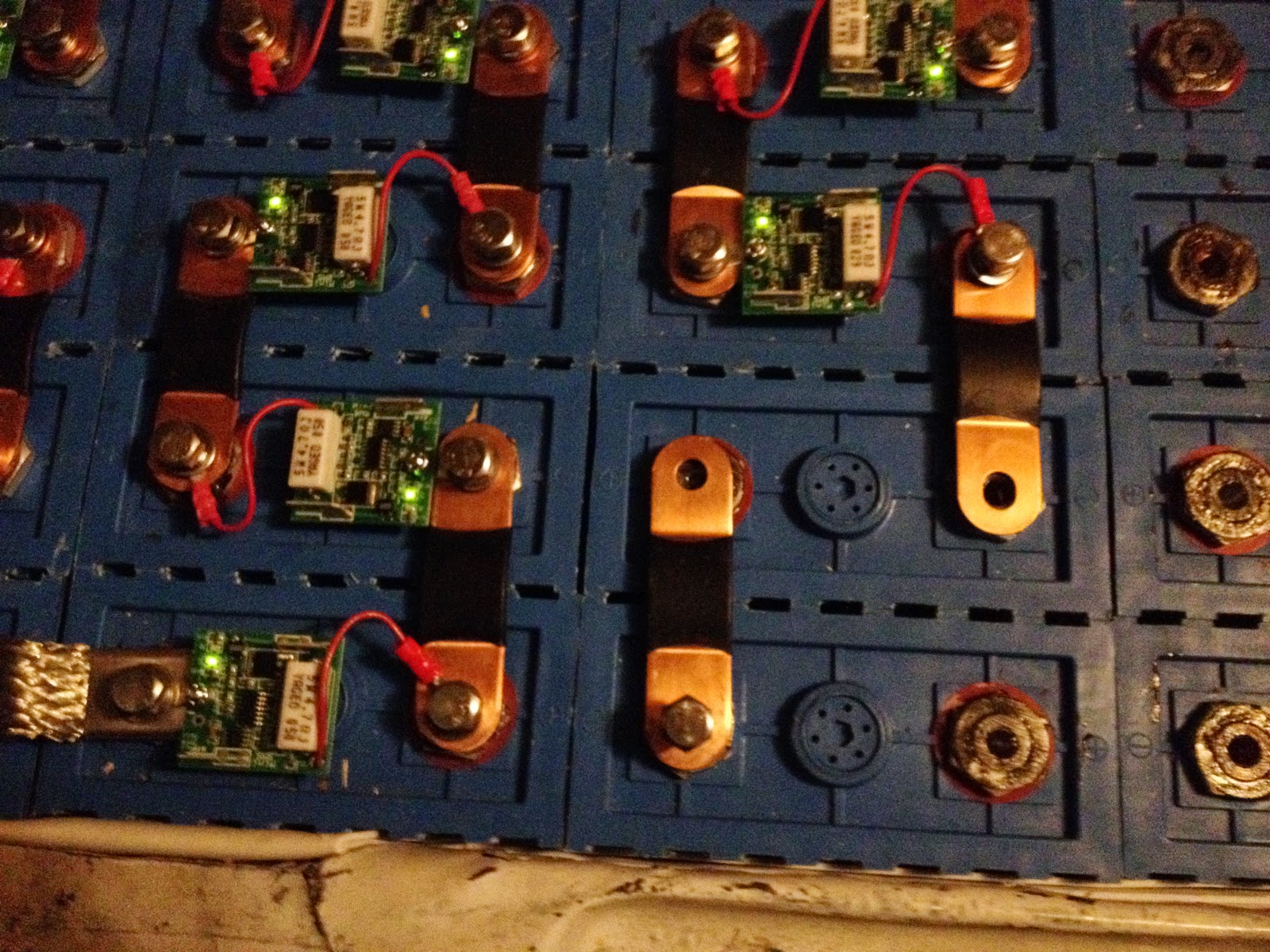

Finally, last night and this morning I interconnected all the cells. There are three steps to interconnecting the cells. First, I smear the terminal posts with a little anti-oxidant grease (NoAlOx or equivalent). I then use an emery cloth to remove the oxide layer from both posts. Then I put battery interconnects, MiniBMS modules, and M8 bolts/washers on. For safety, I follow a routine when putting the interconnects on. First, an M8 bolt is threaded through an interconnect to a cell which is not connected to anything. It is not tightened, it just needs to be enough to keep that end of the interconnect from moving. The interconnect in the lower middle has just had this done:

Next, I attach a MiniBMS module across the previous cell in the string, making sure to put the negative terminal on the negative post:

I tighten down both bolts finger-tight (I will later use an inch-lb torque wrench to finalize the connections). With that done, I remove the M8 bolt that I previously placed:

This is done in this specific order to prevent unintentional short-circuits. Without doing it in this order, it is possible that the interconnect you are working on will rotate over and close the circuit with the adjacent string. This would be Very Bad - there are places on the battery string where 26 volts of potential exist between adjacent terminals. The cells can deliver 1000A or more of current for a significant amount of time (tens of seconds). A 26+ kW plasma event would be a very bad day, indeed (and you would not want to put your hand in there to disconnect anything!), leading to at least several destroyed cells and BMS modules, and at most a vehicle-destroying fire or even severe injury or death. Obviously, I experienced none of those things. You will also note that my finger socket drive and socket are wrapped in electrical tape to reduce the chances of unintentional short-circuits.

With safety always in mind, I completed the interconnect of all the cells. Here is the upper rear box glowing happily:

And the lower rear box, also happy:

During this process, I found one dead cell and one cell with a loose remote BMS wire. This stymied me for the evening, but I was back at it this morning, finishing the front box:

and hooking up the BMS modules under the seats:

With 96 cells all happy, I hooked up the service disconnects, and measured the voltage at the junction box:

321.9 volts - about 3.35 volts per cell - perfect! Next up, tuning the controller.